Water underfloor heating, how the temperature is regulated?

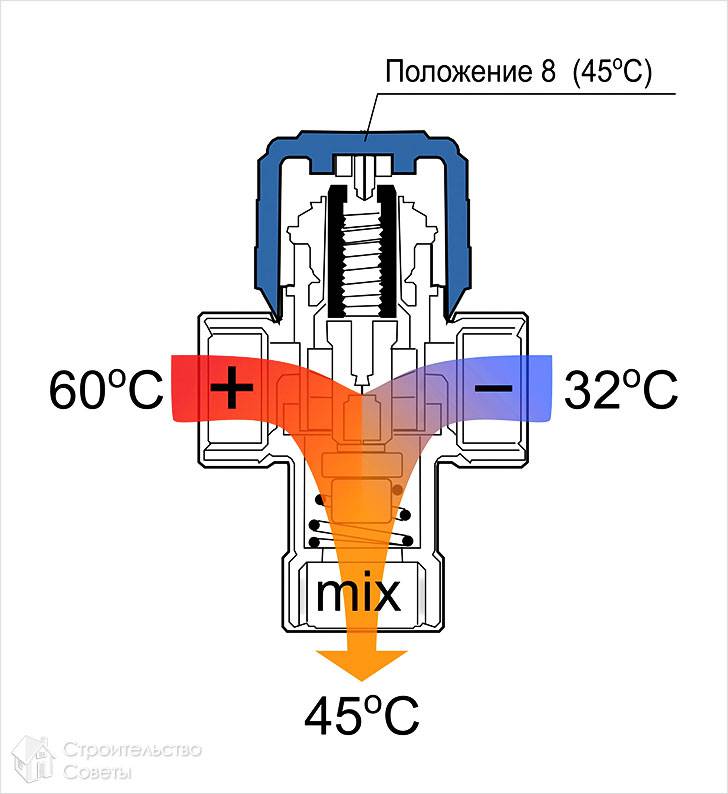

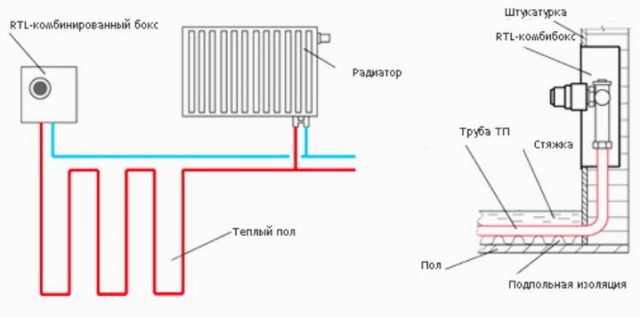

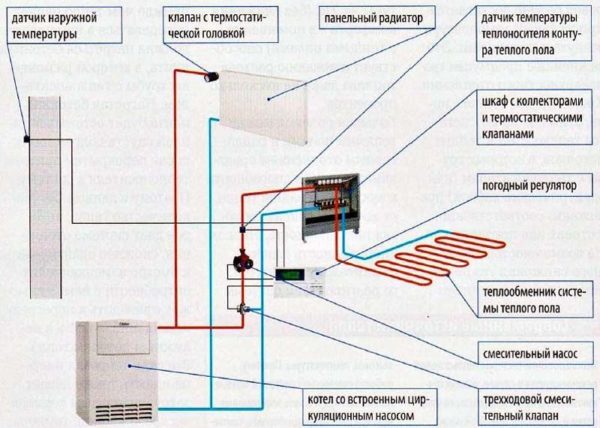

A water heat-insulated floor is a low-temperature heating system. A coolant flows in it, the temperature of which rarely exceeds 41 ° C. Thus, if we reduce the temperature on the boiler to 50 ° C, then the radiators (I cite as an example) on the second floor will already be cold, and on the first floor, where we have a heated floor system, everything will be also hot. This is how the mixing unit for a water-heated floor works. About what it is and how to make a water heat-insulated floor here.

The thing is that the control unit for the water heated floor is not connected with the boiler automation and is implemented on a three-way thermostatic valve. He is responsible for supplying a heat carrier with a certain temperature to the system. If he is not there, then we will be able to walk on the floor only in slippers with thick soles and feel like in a frying pan..

The water underfloor heating control unit regulates the amount of hot heat carrier coming from the boiler and mixes it with the already cooled heat carrier, which returned cooled down through the system. In this way, the temperature of all water circuits of the underfloor heating is regulated. This water underfloor heating control unit is usually called a mixing unit. As the name implies, it mixes cold water into hot water and creates the optimal temperature.

If you have already installed such a heating system, then in order to adjust the temperature, you need to find the same control unit for a water heated floor (mixing unit) and turn the existing thermostat (usually clockwise to decrease the temperature and counterclockwise to add) (by in the picture green regulator discrete value +/- 1 ° C).

Important! The temperature control of the underfloor heating system is gradual. We added 1 – 2 ° C, you need to wait at least 2 hours. This is due to the high inertia of the system. There will be no quick change. Keep this in mind.

The standard mixing unit has a discrete value in regulation and is usually 1 ° C. Those. one click 1 ° C add or decrease – wait.

The concept of regulating a water floor system

Adjusting the temperature of a water heated floor is the task and maintenance of such parameters at which a certain microclimate will be created in the room.

These settings must be made so that the high-quality and flawless operation of the system is not disturbed and the temperature regime created by it suits those in the house, apartment or room.

Adjustment can be made:

- on mixing units;

- at sources of heat energy supply;

- while maintaining the set temperature.

Existing control systems for adjusting the temperature indicators of the underfloor heating collector are applied in accordance with where the setting is carried out and by what method it is performed.

Adjustment features

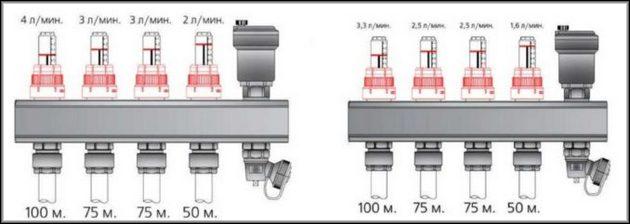

For each individual room, there is a separate adjustment of the rotameters. The control is carried out according to the scheme of the installed circuits

It is recommended to perform balancing according to the following instructions:

- The total amount of the coolant passing through the collector in one minute is determined. Indicators are taken in liters. The resulting value is taken as 100 percent..

- The percentage flow rate of each individual water circuit is calculated. The result is converted to liters per minute.

- The flow meter adjusts the amount of liquid supplied to the pipeline.

By doing this, you can carry out a long-term correction of the water circuit. To indicate the actual parameters, it is necessary to observe the indicators of the flow meter. According to observations, it is possible to accurately determine the flow rate of the circuits connected to the collector.

The flow meter is adjusted depending on the installed model. After connecting the device to the manifold, a preset should be made by setting the initial position, which allows access to liquid.

In flowmeters without a built-in valve, an additional shut-off device is used to set the “open” position. In this case, balancing is performed during the operation of the system..

Combined flow metering devices can be preset using full turns of the built-in valve. Each turn allows the clearance to be reduced by the set value.

The correction of the flow meter of the underfloor heating system is carried out taking into account the control of the fluid velocity in one minute – from 0.5 to 5 liters.

Before you start adjusting the flowmeter, you should check the condition of the installed circuit. Trial testing is necessary to exclude the presence of leaks in the circuit, which can cause distortion of readings in the device..

The flow meter is an essential element in a multi-circuit floor heating system. The device allows for an even flow of liquid into all individual pipelines. In order for the heating equipment to function as efficiently as possible, it is necessary to choose the right flowmeter, as well as carry out its installation and adjustment in accordance with the technical requirements..

Finally, the heating system of my house is assembled. The boiler has started up. Let me remind you that I decided to heat my house only with warm floors. Although there are not many rooms in the house, in order for the comfort in all rooms to be the same, it is necessary to adjust the underfloor heating. This is how the underfloor heating is set up, we will talk in this article..

Setting up a warm floor is not as difficult as it might seem at first glance. Generally speaking, setting up a warm floor consists of three stages. First, balancing the underfloor heating loops, then setting up the pumping and mixing unit and finally setting up the controller if you decide to automate the heating system. I decided to completely automate the heating system in my home. Therefore, I purchased a controller, servos and temperature sensors. Let’s take a closer look at the first stage of the setup, since the success of the entire setup depends on how well it is done..

Optimum temperature parameters

Setting up a water floor heating is carried out depending on individual needs. Someone likes it when the room is warm, while someone prefers invigorating freshness, even in the most severe frosts. But despite this, there are general standards that were developed taking into account sanitary standards, these include:

- floor heating up to 28 degrees;

- in the presence of another source of heat or when living in the room all the time, the ideal level from 22 to 26 is the optimal conditions for a person;

- if this type of heat source is the only one, or it is in the bathroom, corridor, on the balcony, or in a house where they do not live permanently, it is permissible to raise the degree to 32.

Therefore, when regulating water floors, in addition to your preferences, so that the microclimate in the apartment is healthy, these standards should be taken into account.

Temperature regime

The principle of operation of a water underfloor heating is different from the functioning of other heating devices. The main difference is in the level of heating of the coolant. The radiators are supplied with water heated to 80 degrees, for water floor contours a maximum of 42 degrees. At this temperature, the heating of the floor covering will reach 26 degrees..

There are two methods for adjusting the temperature of water underfloor heating:

- Exercising control in the collector supply unit, by mixing waste water. This is achieved by equipping a three-way valve with a thermostatic head. When working, the temperature of the water is taken into account, and not the air, and a constant volume of consumed liquid is provided, with a slight fluctuation in its temperature.

- Restricting the flow of heated coolant into the pipes. This also requires a thermal head, which is located on the 3-way valve and is used to shut off the return flow. In this case, the supply and return valves are connected to the bypass, through which the flow is regulated by a restricting valve. Since underfloor heating is inert, water is supplied to the pipes at a nominal temperature, and only its consumption changes.

In both methods, the thermostatic head in operation is repelled by the return temperature.

System refueling rules

It is impossible to properly adjust the functioning of the water structure if the volume of liquid in the pipeline changes independently. This can happen if there is air in the system – see the instructions on how to bleed the air from the heated floor yourself. Therefore, it is important to both professionally mount the structure and fill it in correctly..

For high-quality filling of the system, both collector branches should be equipped with automatic air vents. The filling of the floor hinges should be carried out separately from other heating devices. The generator and radiators are pre-filled. Manifold inlet valves are closed before refueling..

To properly start the floor, you need to connect a hose from a water supply source or pump to the supply tap, and a hose for air outlet to the return..

It is necessary to start filling the water floor from the collector and its distribution units. To do this, the flow meters of the supply valve open to full, at this moment the taps on the return should be turned off.

The loops are filled one by one, the water is started up until from the bleed hose, it will not flow clean, and without air bubbles. The water should be started with a small pressure, this will make the process of air exit from the pipes more even. After threading all the loops, the device can be turned on.

Working with collector flow meters

Underfloor heating balancing means the definition of norms for each loop. Indeed, from the size of the floor branch, so that in the process of passing through it the coolant cools down according to the calculated value, the amount of water is required different. The volume of liquid that the loop passes through is the thermal load on it.

It is not uncommon, it is recommended to determine the flow rate of the coolant, starting from the power of the pump, that is, the volume of the incoming fluid is divided proportionally by the length of the loops. However, it is worth abandoning this method, since it is not easy to accurately calculate the size of each coil using this method..

In addition, calculations in this way lead to a discrepancy between the pressure in the hinges and the calculated value, which makes it impossible to customize the structure..

The very same regulation process with flow meters is simple – an article with step-by-step instructions. The throughput of the device is adjusted taking into account the model, either by turning the body, or by the stem using a key. The device displays the amount of water in liters passed per minute, you just need to set the desired value.

Basically, always, when adjusting the throughput of one loop, there is a change in others. Therefore, the process should be repeated sequentially with each flowmeter. Significant failures indicate that the valve has poor flow capacity, or the circulating pump has low flow.

Hydraulic leveling system

Warm water floors are a reliable and safe design. But for it to really be that way, it needs to be set up correctly. How to regulate water heated floors in a private house – for this it is better to equip a collector group equipped with flow meters with a working pressure of 6 bar. If the house is equipped with central heating, then this capacity is not enough.

If there are servo drives on the manifold, the water flow is automatically adjusted as needed. However, the preliminary configuration still needs to be done. In the absence of this drive, you cannot do without such adjustment at all..

You can calculate the flow rate of the coolant using the formula:

Gsp = Q / (1.163 * Δt), in which

- Gud is the specific volume of water per m2;

- Q – floor power indicator;

- Δt is the difference between the temperature of the heating agent during supply and output;

- 1.163 – correction factor.

In the future, to calculate the volume of liquid that passes through the loop, you should multiply the specific flow rate by the surface area.

The simplest option for hydraulic alignment:

- calculate the volume of water for each loop by multiplying the floor area where this contour is laid by 8.6 (average);

- start the pump at first speed;

- set the thermal head to 30 degrees;

- check that the liquid passes freely through the loops, and all the air has escaped;

- adjust the flow device on each circuit so that a value is obtained equal to the water flow rate that you calculated.

These actions are pre-adjustment, that is, in fact, during the operation of the warm floor, additional adjustment will be required, taking into account personal preferences for comfort.

Three-way valve capabilities

If the manifold has a three-way valve, then the adjustment is done using the servo. In this case, the control over the indicators will be carried out by the mixing valve. In the process, the three-way valve can be turned as desired, and as many times as necessary. Setting up the mixing valve is more difficult..

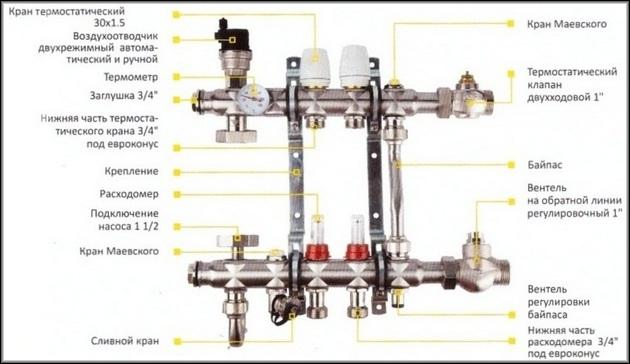

Why do you need a comb for a warm floor, we will analyze its structure and principle of operation, how to choose, instructions with photos and videos, how to install and configure or do it yourself.

There is another possibility to adjust the heating floors – using a modular mixer, it consists of:

- three-way crane;

- thermometer;

- bypass;

- pump for circulation of liquid;

- thermostatic head;

- relay.

This set costs a lot, but its efficiency is high. There is a prerequisite for the functioning of this module – European assembly.

Another method of adjusting warm floors is to install a servo drive and a thermostat. The thermostat notifies the servo drive about a decrease in the room temperature, and about the need to supply a heated coolant. This method works even when assembling the collector with your own hands..

A warm water floor is a complex structure, and deciding to build it in your home, you need to be aware that it is not enough to mount the system, it is necessary to periodically adjust it according to the instructions. And it is important to understand this process, otherwise the floor will not meet your expectations..

Three-way valve and mixing module

When equipping the collector with a three-way valve, the adjustment can be carried out using a servo drive. In this case, the mixing valve will control the temperature reading according to predefined parameters. In this case, you can turn the three-way valve several times and as you like, but with the adjustment of the mixing valve, everything is much more complicated..

If you connected underfloor heating to centralized heating at your own peril and risk, then just the presence of a mixing valve will avoid side problems. Your neighbors will not determine in any way about the presence of warm floors, since there will be no temperature imbalance.

Another method of adjusting the temperature in warm water floors is by using a mixing module. This module in its kit has the following components:

- Three-way valve.

- Thermometer.

- Bypass.

- Circulation pump.

- Thermostatic head.

- Maximum allowable temperature relay.

Although this whole kit is expensive, the efficiency of the mixing module is very high. Nevertheless, the mixing module works only if it is assembled according to the European model. In the heating system, the coolant must have a temperature of at least 65 °. As for the underfloor heating system, the mixing module dilutes the heat carrier and launches it into the heating circuits according to the set parameters. In our country, temperature control is often carried out on the boiler itself. This leads to temperature imbalance..

There is also another method for how warm water floors can be adjusted. For this, a servo drive and a room thermostat are mounted. Based on the room temperature, the thermostat gives a signal to the servo drive about the supply of hot coolant.

This technique works even with a homemade manifold, even with a mixing module, even with a three-way valve. It all depends on your financial capabilities.

So, we examined several methods of how you can adjust the coolant in the underfloor heating system. If you use other technologies and techniques, then we will be interested to know about them. Write your comments at the end of this article.

Group regulation

Group regulation consists in reducing or increasing the amount of supplied heat carrier, in increasing or decreasing temperature indicators, carried out in automatic mode, which, of course, provides an accurate result and makes the regulation process itself convenient.

The regulation is carried out according to the schemes of constants and climate.

According to the constant circuit, regulation is carried out using thermal heads mounted on the valves. For a simple way to adjust the warm floor, see this video:

If it is necessary to increase or decrease the temperature values obtained during the operation of the underfloor heating, the system expands or narrows the capillary tube, which regulates the valve opening until the required temperature regime is established.

How to regulate the climate according to the scheme is determined by the automation itself. In accordance with the ambient temperature indicators, the system automatically determines what temperature needs to be obtained, and for this it gives a command to close or open the valve.

What task does the make-up valve solve?

Actually, the automatic make-up valve, the design of which provides for two or three inputs, is designed to maintain a thermal balance in the house in the presence of several circuits.

The valve can be two-way, designed for mixing boiling water with cold water. By increasing or decreasing the flow of hot water, we get a heat carrier with a particular temperature.

This process is regulated by a thermal head installed on the valve. It does an excellent job of protecting the system from excessive heating, but the valve itself does not have too much flow capacity..

Two-way valve

Therefore, two-way devices are installed mainly with small heating areas. By themselves, they are very reliable, and can be connected in parallel if there are several heating circuits..

Its disadvantage is that hot water is distributed unevenly in this case, therefore, when installing multi-circuit heating, valves with three inputs are mainly installed. Let’s talk about them in more detail..

Individual and complex adjustment

Individual floor control by zones or rooms is carried out using sensors, which are installed in each room.

Group control does not replace individual control, since with the latter option, each room has its own microclimate, and with the first, the entire system operates in one temperature mode.

Complex regulation is a method that combines group and individual regulation methods and allows you to adjust the temperature in the whole house and in each room separately..

Crimping pipes for underfloor heating

Before starting the heating system for the first time or after a long period of inactivity (6-12 months), it is necessary to release the air accumulated in the pipes. This is the first step in adjusting a warm water floor, which is carried out manually, regardless of the principle by which it functions..

In the case when the pipes of the underfloor heating are poured with a concrete screed, it is allowed to start the system only when it dries.

In some special cases, when frosts have already come, and there is a strong delay in repairs, it is possible to gradually start underfloor heating with a smooth rise in temperature within 1⁰C per day. At least 2 weeks must pass from the moment the screed is poured to the start of the system..

Crimping water floor heating

The issue of floor setting is relevant at the beginning of each heating season. The process of filling the system is performed manually, despite the possible presence of built-in sensors. Before starting, make sure that all floor loops are closed, check the valves on the distribution manifold.

The main heating system is filled first. Then the supply and return valves on one of the loops are opened and the circulation pump is put into operation. The turnover is minimal. The contour should gradually fill. At this time, the boiler turns on with a preset temperature in the range of 30-40⁰С.

Having controlled the supply and return of water in the open loop, it is required to close the valves and repeat the filling process from the next one. All actions are carried out gradually until the system is completely filled and de-aerated. Then one more stage – opening all valves.

The warm floor is an inertial system, so the reaction to adjusting the operation of the circuits will not be instantaneous. You will need to wait some time (from two to three hours to a day, it depends on the complexity of the system) and then evaluate the mode of operation, the result on each of the loops. This time range is needed for contours of different lengths, type of installation, thick or thin screed and pipe diameters.

Do I need a thermostat for a water-heated floor

A thermostat for a water underfloor heating is a device with which you can control the heating system, regulate the heating of the heat carrier and set the optimal temperature in the room. The task of the block includes the following:

- Timely turn on and off the system.

- Maintain the required room temperature.

- Carry out automatic heating of the room at the required time.

- To save energy.

It was noticed that after installation, the room temperature controller for water-heated floors can save up to 30% of the costs required for heating the coolant. Of course, there are folk ways to control the temperature of the liquid in the heating system, but, as a rule, they are ineffective, inconvenient and often lead to disruptions in operation..

One of these methods is mechanical temperature control with a tap. Control occurs due to a decrease in the circulation rate of the coolant and, accordingly, a decrease in heat transfer. The disadvantage of adjusting with mechanical flow meters is the need for constant monitoring of the landlord and the low efficiency of the solution.

According to customer reviews, a mechanical temperature controller for a water-heated floor often causes air locks in the system. A sharp change in the pressure and temperature of heating the coolant, leads to airing and loss of performance of the water circuit.

According to the instruction manual, manual adjustment for underfloor heating is allowed. Practice shows that mainly mechanical regulators are installed by those wishing to save on components. The relatively low cost of purchasing an electronic temperature control unit pays off by reducing the cost of heating the coolant.

What is a thermostat

Underfloor heating system implies the installation of heating elements under the floor covering, followed by connection to the mains. This is done not directly, but through a control device – a thermostat.

Naturally, this heating system is equipped with a temperature sensor. The installation of this device is carried out using a flexible plastic tube installed directly into the floor screed..

The latest models of thermostats are equipped with a programming system, which is good news. This is quite convenient because it allows the owner to determine when to set the heating system to economy mode, and when to use it at full capacity for maximum comfort, for example, after a long day when the whole family has returned home..

The price for programmable regulators is slightly higher than for conventional models. However, thanks to the potential for savings, the difference in price is leveled out after 1-3 seasons. Read also: "Which temperature sensor for underfloor heating to choose and how to install it correctly".

The following types of thermostats can be distinguished:

- Devices with economy mode. It makes it possible to reduce the temperature in the room for a time when there are no tenants in it, by a certain number of degrees, which will slightly reduce electricity consumption.

- Thermostats, complemented by a programmable timer. Temperature control is carried out by means of a set timer program. The timer sends commands to the temperature controller, thus adjusting the heating power at a specific time.

- Intelligent programmable temperature controllers. On the screen of such a display, you can set the alternation of preset modes. The device itself determines when and which program to execute, based on certain factors.

- Temperature controller with limit probe. It makes it possible to set extremely low and high values of floor heating at a specific air temperature. Thus, you can be warned against possible overheating, while maintaining the integrity of the existing flooring..

The principle of operation of the temperature controller

The main function of the regulator is to control the water underfloor heating. Depending on the complexity of the device, both full and partial automation of the room heating process is possible..

According to their principle of operation, all thermostats can be divided into two main categories:

- The simplest manual controls are, in fact, an ordinary crane. The shut-off valve regulates the pressure in the heating system. Manual mode has many disadvantages, but is often used mainly for small spaces..

- Thermostatic regulator – the principle of operation is in many respects similar to the one that has manual control, only the signal to supply the coolant is performed by a special sensor. When a certain temperature is reached, a signal is given to turn on the circulation pump. All actions take place according to a pre-set program.

Programmable thermostats-regulators are capable of simultaneously controlling several circuits at once, changing the heating temperature depending on the time of day and weather conditions. Automatic pressure control controller allows you to set the most comfortable mode for a person.

There is another economical adjustment option. A temperature relay is placed on the return manifold. The device is powered in such a way that the on-off of the circulation pump is controlled through a thermostat. The required heating temperature is set. The device of a home-made regulator is quite simple, but not suitable for simultaneous heating of several zones.

Briefly about the thermal sensor

The kit includes a thermostat and a temperature sensor. The temperature sensor is installed using a plastic corrugated tube. The corrugated sensor is laid in the screed.

The new sensors have a programming function. Thanks to this function, the owner can adjust the temperature controller so that during his absence the warm floor will work in economic mode. At the same time, for a certain time before the arrival of the owners, the device switches to normal mode, thereby heating the room to the required temperature. Despite the fact that the cost of a programmable thermostat is more expensive than the usual one, it is better not to save on this, because in 2 seasons it pays off.

Is it obligatory to use them

With the help of the thermostat, you can choose the most comfortable temperature

If the main task of the buyer is to save on the arrangement and operation of the warm floor, the purchase and installation of a thermostat is not at all necessary. But when making this decision, the user is deprived of the following features:

- set the required temperature, which is considered the most comfortable for the feet of adults, and especially children;

- change (correct) the picture of the distribution of thermal zones, depending on the current situation;

- do not waste energy unnecessarily for heating areas of the floor covering that do not need it.

Using a properly configured thermostat avoids another uncomfortable situation when the floor is overheated. This usually happens when the temperature exceeds 25-27 degrees. In addition, strong heating negatively affects the upper (final) floor covering, since even the most heat-resistant varieties have an acceptable temperature limit.

When the maximum temperature values are exceeded, irreversible processes begin in the material, leading to linear expansion and deformation. At the same time, drying out, warping and divergence of the seams are observed, followed by breakage of the tool joints..

A well-tuned thermostat allows significant energy savings

The following important points should be considered regarding energy savings:

- with proper installation, accurate tuning and competent operation of warm floors, the elements built into it consume energy unevenly;

- the maximum occurs at the time of starting the system and the initial heating of the coating to the specified temperature;

- during subsequent operation, only short-term switch-ons follow, allowing to maintain the required level of surface heating.

Even without the use of an “intelligent” regulator, the total consumption is very insignificant. By installing a well-tuned thermostat, savings will reach record levels, since the floor in this case will only heat up when it is really needed.

Which thermostat is better for water heated floors

For underfloor heating, you need to install a thermostat that will simultaneously combine several important functions:

- Smooth electronic temperature control – only in this case the appearance of air locks is completely excluded.

- Possibility of simultaneous temperature control in several rooms. The system of zone automatic control of the temperature of the water-heated floor is necessary in cases when several rooms are heated, or several water circuits are used in one room at once.

- Mounting type – the equipment is divided into external and built-in regulators. To mount the latter, you have to make holes in the wall. Remote controls can be installed anywhere in the room in a special box.

- Type of control – equipment for reliable automatic control of the temperature of a warm water floor, as a rule, has two sensors that simultaneously record the heating of the floor surface itself and the temperature of the air in the room.

The control unit carries out control taking into account two indicators at once. Room low-current thermostats are equipped with either a built-in (to control the air temperature) or an external sensor (according to the temperature of the coolant).

- Functionality – regulators can be programmable, mechanical and non-programmable. When choosing the necessary equipment, you should take into account the need for autonomous operation of the system..

Comfort lovers should choose a programmable thermostat. The control unit has different modes that allow you to turn on floor heating at certain hours, depending on weather conditions, etc..

Some programmers can be controlled by remote control and GSM notification system. The disadvantage of the programmable solution is the high cost of the unit and the fact that installing the thermostat on a water-heated floor with your own hands is hardly possible..

- Principle of operation – there is a two-way and three-way adjustment method. In the latter case, thermal energy is saved as much as possible, since the heated coolant from the boiler is added only if the liquid in the water circuit cools down. In the two-way method, hot water is added with reverse mixing or continuously.

The thermo-mechanical regulator is best installed for small rooms: bathrooms or kitchens, with 1-2 heated circuits.

Mechanical models

Mechanical thermostat AURA LTS 230

Mechanical thermostats on the market are inexpensive devices that are simple in design and maintenance. The choice of control methods in these devices is not great. On their front panel, there are usually only two elements – a power button and a temperature controller in the form of a wheel with a scale applied next to it. In addition, it provides the simplest indication of the on state, made on a conventional LED..

The advantages of such regulators include simplicity of design and affordable price. However, the accuracy of setting the temperature regime is very low, which does not always allow achieving the desired result. Another significant drawback of these devices is the lack of an option for programming operating modes..

A tangible saving in energy consumed from the mains cannot be achieved through such a thermostat. Despite this, individual users are attracted by the simplicity of their device and an affordable price..

Programmable devices

Multichannel PID thermostat with USB Termodat-19E5

This group includes devices that are usually denoted by the word “smart”, since they are distinguished by the presence of a large number of options. As a rule, such devices provide for a separate built-in temperature sensor and the ability to switch state control modes in two environments (“by floor” and “by air”). But their main advantage is the ability to program the device at will, setting the desired temperature within a certain period of time. Usually they are set for the selected hours during the current day or for the days of the week (taking into account weekdays and weekends). In especially “advanced” models of such regulators, it is possible to program via the Wifi network with a simultaneous connection to the Internet..

Remote control (with remote control)

This type of regulator is represented by models from “Eberle”, “Gira” and “Livolo”, consisting of two interconnected modules – stationary and portable (remote control panel). The first is supplied with electrical wires from sensors and relays of underfloor heating, which determines the choice of a place for its placement within the room. The operating modes of the heating system can be controlled from any zone limited by the range of the radio communication channel.

A number of manufacturers (“Livolo”, for example) release special applications for their products, by installing which it is possible to control the switching on of the equipment from a mobile phone. In some models of regulators, the console kit includes remote thermal sensors that measure the air temperature at their location.

How to connect water floors to a thermostat

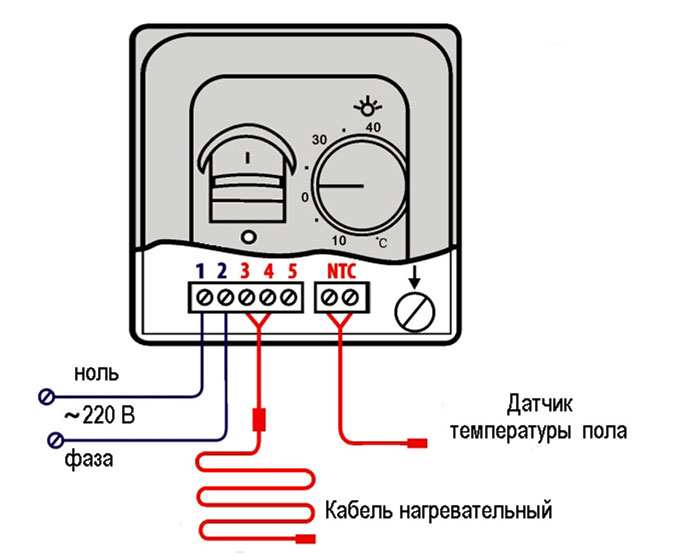

A detailed diagram of connecting the thermostat to a water heated floor is necessarily included in the kit provided by the manufacturer. Installation work is carried out as follows:

- A box for a thermostat is installed.

- Thermostat is mounted.

- A temperature sensor is installed, it is placed between the bends of the water circuit.

To position the regulator correctly, raise it approximately 120 cm from floor level. The connection diagram of the thermostat necessarily implies the installation of a servo drive that regulates the water supply.

Even before starting work on laying water heated floors, it is necessary to draw up a complete list of the necessary equipment, including a thermostat, sensors and a servo drive.

How to properly regulate a water heated floor

Regardless of what exactly it is planned to regulate the heating of the coolant, you should remember the basic rules that limit the operation of warm floors.

- Most floor coverings have limitations related to the heating temperature of the material surface. So for laminate and parquet boards, the limit is set at 28-29 ° C.

- The norms specified in SNiP limit heating in the range from 25 to 35 ° C. As practice shows, at 29 ° C, the most comfortable conditions for human health and life are provided..

It will not be possible to accurately set the temperature using a manual mechanical thermostat. The choice of electronic programmers will be optimal, especially if it is planned to regulate the heating of several heating zones.

How to regulate warm water floors

A water heat-insulated floor allows you to create a wonderful indoor climate. This is achieved by uniform distribution of heat energy. But for the long-term effective operation of floor heating, you need to figure out how to regulate warm water floors. This article will cover several adjustment methods..

How to properly run underfloor heating

To put into operation underfloor heating, you must wait until the screed is completely dry. This can take up to three weeks. If time is running out, you can speed up the drying process by adding 1 degree of heat every day. This can be done only after 14 days..

Moisture should come out of the concrete evenly. Otherwise, the screed will begin to crack, and this will violate the integrity of the heating cake..

All heating circuit valves on the manifold must be fully open immediately before starting. The three-way valve also opens to the maximum. Finally, turn on the circulation pump. After this stage, you can start adjusting the temperature of the coolant..

Safety engineering

Any work on the installation of electrical equipment must be carried out in compliance with basic safety rules. Failure to comply with these can lead to disastrous consequences..

The basic rules include the following:

- before carrying out work, make sure that the entire room, or a separate room in which the sensor is installed, is de-energized;

- do not start a device that is disassembled;

- operation of the regulator implies a temperature regime from -5 to 40 ° C;

- clean the thermostat from dust in a timely manner;

- cleaning the device must be carried out with means that do not contain solvent or benzene;

- carry out repairs if only you are 100% sure of your abilities, while you will need to figure out how to remove the thermostat for a warm floor;

- make sure that the power of the system does not exceed the permissible limits stipulated by the manufacturer of the thermostat.

Regulator installation sequence

The process can be roughly divided into a series of sequential steps. If you follow them, all work will go without nuances..

There are 5 such stages:

- Make a hole in the place where the device is attached – a punch or impact drill is best for this. The dimensions of this device should make it possible to install the box. In addition, create ducts for cable management and sensor installation. Install the installation box into the finished hole.

- The wires can now be laid. The heating system power cables should be routed to the box, and also connect the temperature sensor wires.

- Install the thermostat. It’s pretty simple, you just need to fix the device in the box..

- Now you need to connect the main parts of the system. This stage requires a special approach and adherence to the instructions attached by the manufacturer, because the sequence may differ slightly in each specific model..

- Replace the front panel with the supplied mounting screws. With the help of a building level, you need to check that the regulator was set strictly at the level. Then you can close the lid and turn on the power. If you did everything correctly, the thermostat screen will turn on and the underfloor heating indicator will light up. After that, you can start setting up the regulator..

According to the advice of experts, it is possible to start the underfloor heating system into permanent operation only after 3-4 weeks after the screed has been poured and the floor covering, namely the tiles, has been laid. If you turn on the heating system ahead of time, then the screed may spread and the floor covering will become unusable..

The owner only needs to measure the resistance between the heating elements with a special tool and compare them with the recommended indicators provided by the manufacturer. If everything satisfies, then you just need to wait for the final hardening of the screed. Only then can the finished heating system, equipped with a thermostat and a temperature sensor, be started up permanently..

The main stages of installation of the thermostat

- Preparing the site for the regulator. It should be located at a height of 1.2 – 1.5 m from the floor.

- Installation of an electrical box and supplying 220 V power wires to it.

- Slitting the wall under the corrugated tube in which the temperature sensor is located. The tube runs from the thermostat to the floor.

- Underfloor heating installation (see instructions in the relevant section).

- Placement in the floor of a temperature sensor that detects the temperature of the floor surface. The sensor is installed in a corrugated tube, which protects it from the concrete screed and makes it easier to dismantle in case of failure. Cold lead-in leads at the ends of the cable are inserted into the groove.

- Filling the screed.

- The actual connection of the thermostat.

The mounting ends of the cable, temperature sensor and power wires are connected to the thermostat terminals in accordance with the instructions for the device.

- Installing the regulator in a back box.

- Sealing the grooves in the wall.

Temperature determination error

Please note that the temperature directly on the remote sensor will always be higher than the temperature in the room, which the regulator shows on its display..

This is due to the depth of the sensor in the screed..

Usually this delta, between t on the floor surface and t inside the screed, does not exceed 5-7 degrees.

Both parameters can be seen on the displays of electronic devices, but in mechanical devices with a wheel, often degrees are not even prescribed around the circumference, but only numbers 1-2-3 are indicated, etc..

With five digits, one division corresponds to approximately 8 degrees.

Degrees are not indicated for a specific purpose, so as not to confuse the user. Put it on the thermostat body + 25C, and the room thermometer in the apartment will show only + 20C.

The majority will immediately have a question why the regulator works with such an error? Has it broken?

No, he’s okay. In this case, up to + 25C, the sensor in the floor warms up, and not the air in the room. That is why manufacturers in mechanics simply indicate numbers so that you, focusing only on your feelings, can choose the most comfortable mode for yourself..

If on your mechanical thermostat exactly degrees are indicated, this means that it mainly works and is guided by its own air temperature sensor built into the body..

The one that connects to it from the outside and hides in the screed only plays the role of protecting the cable from overheating.

Power 220V to terminals L and N through an RCD with a leakage current of no more than 30mA.

The connection diagram of a warm floor directly through a thermostat from different manufacturers is of the same type and looks like this.

High power underfloor heating connection diagram

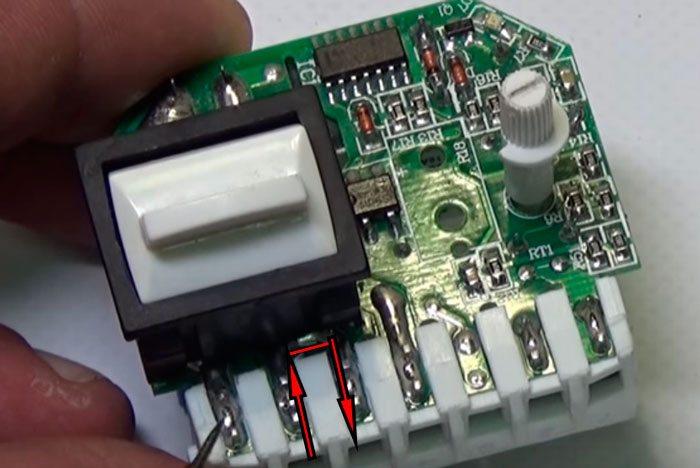

When connecting, be sure to check the power that the thermostat is able to pass through itself. Usually it is designed for a load of no more than 16A (3.7kW at 230V).

This is exactly the maximum value. It is recommended to use the device under constant load no more than 70% of this power.

In this case, the device will serve for a long time and properly. The relay, which commutes the contact, quickly breaks down when overheated. And along with it, the entire device will have to be changed..

For loads over 3.7kW, a modular contactor is required.

The connection diagram in this case will change to the following.

Here, instead of the load, the wires from the regulator go to the contacts of the closing coil (A1-A2), and the heating cable itself is connected to the power terminals of the starter (1-2 or 3-4).

Phasing on the thermostat

A frequent question is whether there is a difference where to connect the phase on the thermostat, and where to zero?

Yes there is. This does not affect the logic of the device’s operation, but it still does not affect the safety.

If you confuse the phase and zero, then when the thermostat is turned off, not the phase conductor will break, but the zero one. Thus, the phase will be constantly present on the underfloor heating cable, which is naturally not safe..

In those devices that have a separate switch on the case, when it is pressed, two conductors break at once, both phase and zero. But this is in the manual shutdown mode, and even then not in all models.

Often, a zero is fed directly through its lane. I went to the terminal and immediately went to the warm floor.

In this case, the switch itself is only responsible for interrupting the power supply to the control board. When automatically triggered by the sensor, only one wire is always broken.

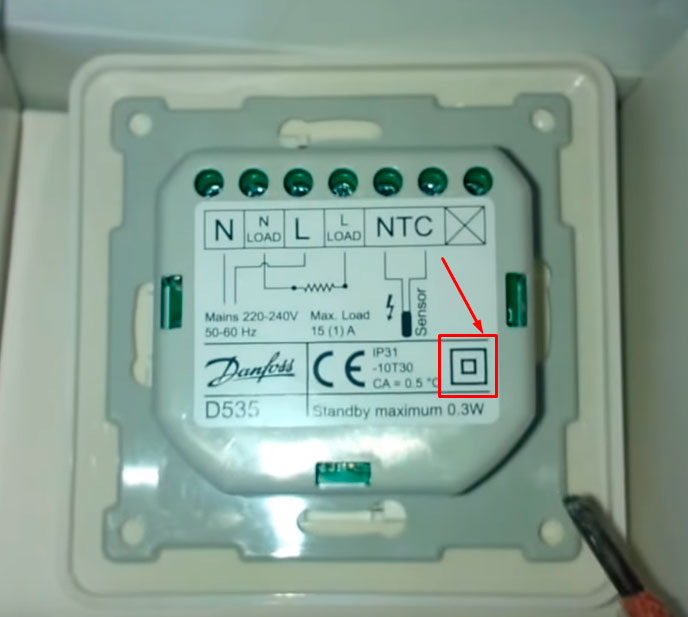

Do I need land?

Also note that the protective grounding directly to the thermostat itself is not started!

It can be a separate, isolated terminal through which the screen of the heating cable is connected to the protective conductor..

On the thermostats themselves there is even a “square in a square” icon, which means – a device with double insulation.

These marks are commonly found on portable tools that do not require a grounding contact on the power plug..

The difference between expensive electronic thermostats and mechanical ones

What super-tasks are solved by smart thermostats stuffed with electronics and a display? It would seem, why buy an expensive product if you can buy a regulator with a mechanical wheel and just set the desired temperature for yourself.?

The fact is that having set a temperature acceptable for itself in the region of 23-25C on warm floors, after reaching it, even with the heating device turned off, the system will continue to gain degrees by inertia until a certain moment.

The same goes for the minimum parameter. In fact, such fluctuations in the room can reach from 19 to 27C.

There is no question of maintaining comfortable conditions with such variations. In smart electronic thermostats, all this is solved by PWM regulation..

This term came from radio electronics. There PWM is pulse width modulation. In heating, this principle consists in changing the on time and operation of the heating elements..

However, as the set point (+ 25C) is reached, heat begins to be supplied as if in small, short pulses (on-off). Due to this, the temperature is precisely maintained in the area of a comfortable.

In this case, you can forget about inertial processes associated with overheating or vice versa with excessive cooling. You won’t get anything like a wheel thermostat..

Thermostat does not work – how to check?

At the same time, do not expect any global changes when replacing the thermostat from one model to another. There is an opinion that if the warm floor does not heat up, then it is worth changing the thermostat to a more expensive one, everything will change by itself.

The air temperature in the room will immediately rise, and where it was previously cold, heat will come. Roughly speaking, a thermostat is a kind of speedometer in your car..

You can draw 300-350 km / h on the speedometer, but if the engine is not capable of delivering such power, then you will not see this speed either. If something is to blame for the poor performance of warm floors, then first of all look at the temperature sensor.

It is very easy to check if the thermostat is working properly. Supply 220V power to it and connect the remote sensor.

Further, instead of a warm floor, connect an ordinary incandescent light bulb to the thermostat. Begin to twist the handle, changing the temperature.

At some point, the light should light up.

Next, hold the temperature sensor in your hand and wait. When heated from your body, a working thermostat will work and the light will go out.

If the sensor is hidden deep in the screed, then you can warm up this place with a hairdryer and wait for the same effect. When the lamp does not respond in any way, this indicates a malfunction of the device..

The fastest way to repair in this case is to transfer work from the floor sensor to the air sensor built into the housing..

The ends of the cable on the device from the floor temperature source will have to be folded back, and the settings of the device itself will be rebooted.

All this will work correctly if the thermostat is installed directly in the heated room..

If you have an electronic thermostat with PWM control, then with the above test method, it is not recommended to heat the sensor too quickly with an extraneous heat source. What is it fraught with?

Firstly, the thermostat will immediately register an abnormal increase in heat and will work ahead of time. Secondly, the “smart brains” of the device will forcibly turn off the heating for the next 20 minutes..

In this case, the temperature after 5 minutes on the display of the device will be sufficient to turn on, and the start-up and closing of the contacts will not occur. As a result, you will have doubts about the correct operation of the thermostat.

Therefore, fast heat test is ideal for mechanical devices, and be careful with electronic devices..

Overview of the multifunctional thermostat for warm floors

The setting and control of electronic varieties of thermostats is carried out according to factory instructions. As an example, let’s consider a popular (thousands of orders from all over the world + positive reviews) and inexpensive thermostat model from our Chinese comrades.

To start working with the device, first of all, apply a voltage of 220V to it.

After a while, the backlight goes out and the device goes into power saving mode. At the same time, even in the event of a complete loss of voltage, the thermostat remembers and stores in memory all previously set settings..

Therefore, all the parameters were entered once, and then nothing will have to be reprogrammed..

In manual mode, when the hand icon is displayed on the screen, you can set the desired room temperature.

This parameter is set by pressing the arrow buttons (up – down).

At rest, the screen shows the actual room temperature.

To put the device into automatic mode, press the button with squares and the display immediately shows the clock or alarm icon.

In automation, it is not possible to change the previously set temperature threshold using the arrow buttons. Data is tightly tied to a specific day of the week.

This day is also displayed on the screen (1-Monday, 2-Tuesday, etc.).

The time period of the day is shown as a small house with a number (just above the day of the week).

Through it, you can program the heating operation so that at night the floors work at full or vice versa with a minimum load. It all depends on your living conditions.

A total of six time periods can be set.

If you have selected a model with WiFi, the time and day of the week are displayed automatically.

When the heating is working, smoke appears above the house.

For more details on all the nuances of the settings of this thermostat, see the video below..

How to properly adjust the temperature?

The correct setting of a warm water floor is carried out according to the following indicators:

| Premises | Optimal temperature, ° C | Permissible t, ° C |

| Living room | 20-28 | 18-24 |

| Kitchen | 19-21 | 18-26 |

| The corridor | 18-20 | 16-22 |

| Bathroom | 24-26 | 18-26 |

| Bathroom | 19-21 | 18-26 |

In the process of control, you need to set up a device that controls the flow of water, it increases and decreases its supply at the right time.

What does the underfloor heating system consist of??

The owner, opening the box with the heating system, sees a complex interweaving of polymer pipes, pressure gauges, flasks, sensors and valves.

To configure the system, you should study its main nodes:

- The boiler and underfloor heating are connected by two pipes, the largest of all. One by one, the heated water is fed into the circuit, and the second is the cooled coolant returned to the boiler for reheating (return flow). The difference between the temperatures inside these pipes indicates the amount of heat expended in heating. Typically, this is 5-10 degrees;

- There is a circulation pump inside the collector, thanks to which water moves along the entire circuit of any length. Also, thanks to the pump, cold water from the return flow is added to the water supply from the boiler – this is imperative for the system to work with batteries, inside which a higher temperature is required than in the floor circuit;

- The three-way valve valve ensures that part of the water is redirected to the pump to reduce its temperature before being fed into the circuit;

- The main part of the collector is a comb with a pipeline connected by special connectors opposite each other. One circuit is attached to the straight line, the other to the return line. Each of the circuits is a battery that is in the floor, so the owner must understand in which room each circuit is located;

- The flowmeter flask is located near the valve with direct flow, and near the return there is a circuit shut-off valve. The flowmeter works very simply – the deeper its float sinks, the more water flows through the circuit. The flow meter can be used to adjust the flow by removing the red washer to start rotating the handle. The optimal flow is considered to be 2 liters of water per minute..

How to adjust a warm floor with your own hands

Warm floors nowadays are in great demand among the population, since such systems provide a comfortable temperature regime throughout the room. That is why many people are interested in how to adjust a warm floor with their own hands..

How to do the initial floor setting

The initial start-up of a newly installed floor heating begins precisely with the adjustment, and it is necessary to carry it out correctly. This is important not only for the system itself, but also for the operation of the floor covering, which should not be exposed to overheating..

Water pipes can also be mounted on a dry screed, but most often they are laid in a monolith due to the greater heat transfer of such a cake. Regardless of its design, the initial launch of the system is carried out before the finish cladding is made..

The initial start-up is carried out before the installation of the decorative coating

At the same time, residual moisture evaporates from the screed, which is very important when the construction is not carried out in the hot season and the cold is forced to hurry up. In this case, you can set only room temperature (about +20), increasing it by only 1 degree per day.

On a note! Forcing events is inappropriate – gradual heating will exclude cracks in the screed due to sharp linear expansion.

In this mode, the system must work for at least 2 weeks. During this time, the concrete will dry out perfectly, which only has a beneficial effect on most finishing materials that do not like moisture.

Table 2. Adjustment of underfloor heating

Step 1 – fill the system with water | For the first start-up of the system, you first need to fill it with water and bleed air. To do this, open those taps that are supposed to be open during floor work.. It: 1. Flowmeters or valves on the manifold. 2. Three-way valve (if it is with a thermal head, then the value on it should be the maximum possible). 3. Shut-off valves on the supply and return. 4. Air vents. |

Step 2 – bleeding air from the circuits | Water will begin to fill the pipeline, whistling sounds will indicate that it is displacing air. When everything calms down, all taps can be closed, except for the supply to one circuit. This is done so that the pump pressure is concentrated only on it and squeezes out the remaining air. Thus, you will have to pressurize each loop, and then turn off all the taps.. |

Step 3 – adjusting the 3-way valve | In this case, the 3-way valve must be closed – or be at a minimum. |

Step 4 – adjusting the flow meters | Now you need to distribute the water flows along the contours, taking into account their length. As you can see, there is a scale on the body of the flow meter that indicates l / min. You should know the length of the circuit, the pump performance too. Divide one by the other, you get l / hour, then divide by 60 minutes, you get l / min. You underestimate the result obtained by 0.2 (for hydraulic resistance), and set it on the flow meter. |

Step 5 – manifold with tuning caps | If there are no flow meters, and you have manifolds with adjustment caps, open them according to the instructions for the required number of revolutions. In any case, you should achieve the same heating of all circuits.. |

Step 6 – turn on the pump | After setting, turn on the circulation pump at minimum speed, then add one more revolution (medium). Hot water will gradually displace cold water, which will take about 3 hours. |

If before the start of floor heating, the maximum values were set on the flow meters, or they turned out to be different on each circuit, now is the time to adjust them in order to achieve uniform heating. When there is an electronic thermostat in the system, which was described above, set the desired temperature to it – and he will adjust it himself.

Rules for the first start-up of the system

Setting up a warm water floor begins from the very moment of its first start-up after installation. This is an important and crucial stage, which largely determines the reliability and durability of the laid “pie”. Thus, there is a “setting” not only directly to the elements of the heating system, but also the floor itself (screed, floor covering), in contact with the heat from the pipes.

The first start-up of a water-heated floor is carried out before laying the decorative floor covering in order to dry the concrete cake.

The main recommendations are as follows:

- The first start-up of the system is carried out with a dry concrete screed (the usual hardening time of cement-concrete mixtures is from 17 to 28 days).

- If time is short, the repair has been delayed, and the cold has already begun, a gradual start of the system is allowed with an increase in the temperature of the coolant by no more than 1⁰C per day. At the same time, at least 2 weeks should pass from pouring the screed to turning on the floor for a gradual warm-up. So it will be possible to dry the finishing screed faster, eliminating the risk of heat shock, stress and cracking of the cement..

- It is extremely important to dry the screed well before laying decorative coverings, which are especially sensitive to moisture (parquet, laminate, etc.).

The process of starting the system and its heating

It is necessary to put the floor heating system into operation not only after its installation, but also every year before the onset of cold weather. This process consists of several stages:

- Descent through air pipes;

- Filling the circuit with water;

- Adjustment of underfloor heating and adjustment of their operating mode for maximum performance.

Usually, owners put controllers, sensors and programmers on the circuit, the work of which simplifies interaction with the system, but does not exclude the participation of the owner. The first start is always done manually!

Adjusting the underfloor heating step by step:

- Checking valves on manifold-distributors. All of them must be in the “closed” position;

- Check the filling with water (heat carriers) of the heating system;

- Turn on the pump for heating the system at minimum speed;

- Open the return and water supply valves (“Open”);

- Check the filling of the circuit with the coolant and the air discharge through the pipes through the drain (located in the manifold);

- Make sure that the circuit is filled with water and that the air in the pipes is removed by means of a drain on the manifold;

The circuit is filled gradually and slowly, the fewer revolutions the pump makes, the less the likelihood of air congestion in the pipes!

- Switch on the condensing heating boiler;

- Make sure that the coolant is supplied to the circuit;

- Check the return flow;

- Perform a test of the operation of the circuit;

- Close the water supply and return valves;

- Carry out the procedure with each existing circuit.

Having filled all the available circuits, the valves on the manifold are set to the open position. The system does not immediately heat up to the set temperature, since it is rather inertial to heat. The effect will be felt in 10 hours, maximum in a day. The response time is related to the multi-layer arrangement of the floor heating system and the length of the circuit.

Preparatory stage

The question of how to properly configure warm water floors in order to ensure high efficiency and reliability of the system is relevant not only at the first start, but also remains urgent every year before the next start of the system..

We are talking about starting air and filling the system with a coolant. Even if the heated floors are equipped with state-of-the-art sensors and electronic or radio-controlled programmers, the process will not be complete without direct human participation..

This is a kind of starting manual adjustment in warm water floors..

Regardless of whether underfloor heating is used as an independent or complementary radiators, before starting the warm floor, you must make sure that all valves and valves on the distributor are closed – both for supply and return..

If the built-in heating is used as an additional one, then after closing all the loops of the water floor, you must first fill the main heating system with coolant.

Next, you need to open the supply and return on one loop, turning on the circulation pump at minimum speed and allowing the circuit to gradually fill with water without the formation of air jams. This is the basic rule of how to set up a warm water floor. The air will be discharged through the air vent on the manifold.

The boiler can already be started to warm up by setting the temperature to 30, maximum 40 ° C. It is necessary to control the supply of warm water to the open loop, as well as the return of warm water in the return. If everything is normal, the tested circuit works well, the supply and return valves on it overlap, and all operations are repeated with the next circuit. And so on until the system is filled and deaerated.

At the next stage, before properly adjusting the warm water floor, it is necessary to fully open all the valves and be patient, especially in the case of manual regulation without the use of modern automation (controllers, regulators and servos). It is worth remembering that water heated floors are an inertial system that does not respond instantly to adjustments made. You need to wait for the system to warm up and evaluate the temperature mode of operation on each circuit.

It is worth remembering that the time of the “response” of the system to a change made (heating or cooling by controlling the heating temperature of the coolant in the boiler or controlling the volume of the coolant entering the circuits), depending on the length of the circuits, the laying scheme, the type and diameter of pipes, the thickness of the screed, can be from a couple of hours to a day.

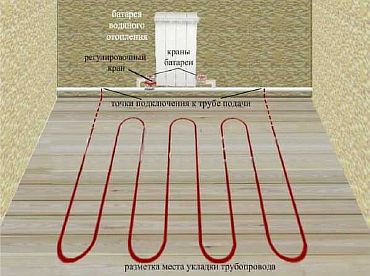

Regulation of heating of water floors

Most often, for arranging water floor heating, they use the connection of heating circuits by means of a manifold, onto which both ends of the pipeline go: one of them supplies the coolant, and the second returns it back. Hot water is supplied to the entrance to each of the heating circuits at the same temperature.

Since the length of the pipelines is different, each of the rooms is heated to a different temperature. For example, for a bathroom this parameter should be 25 degrees, and for living rooms it cannot exceed 22 degrees. To add or decrease the degree of space heating, you need to change the amount of heat carrier supplied to the circuit.

The easiest way to regulate the temperature of a water-heated floor is to equip the collector with special valves for inlet and outlet (for more details: "Floor heating collector diagram – how everything should work"). By turning their heads, you can adjust the amount of heat carrier supplied to each of the circuits. In this case, you have to focus only on your own feelings, and this method of adjusting the heating cannot be called convenient.

The sequence of actions is as follows:

- adjusting valves are tightened;

- wait for some time until the floor warms up;

- evaluate the result;

- tighten the valves again, etc..

Since the temperature outside is almost never the same for even one day, the owners of the house have to turn the valves very often, and manually.

In order to automate and mechanize the regulation of heat supply, special adjusting devices are used: a monitoring and control thermostat for a water heated floor, and an executive servo drive

The thermostats shown in the photo are usually placed in every room where water-heated flooring is installed. In turn, each circuit on the heat carrier feed comb is equipped with servos. According to the signals, they increase or decrease the amount of water supplied to the circuit. Thermostats communicate with specific servos and send control commands to them.

Regulators control either the temperature of the warm water floor or the air mass in the room. At the same time, it is necessary to monitor the temperature regime of the air in the room when heating the floor surface is the only way to heat the house.

There are models on the market that can track both indicators at the same time. In this case, the main parameter of the assessment before setting up water heated floors is the air temperature, and the secondary is the floor..

Operating principle of the underfloor heating regulator:

- The required temperature is set on the equipment case (floor surface or air, depending on the specific model).

- If the parameter deviates in one direction or another, a signal is sent to the servomotors, after which the supply of the heat carrier either increases or decreases. As a result, after a certain time period, the temperature returns to normal..

When the pipes are filled with a screed, it takes time for the entire concrete mass to warm up or cool down. In the presence of a floor heating system, the inertia is less and then changes occur faster.

Variety of regulators for water floor construction

The fundamental difference between different control devices lies in the way of setting the required temperature:

- Mechanical modifications. These devices rarely break down and are affordable. This type of water underfloor heating regulator has a simple scale that makes the adjustment process easy and understandable. The required temperature is set using a rotating disc. Sometimes there is a lever on the front panel of thermostats for water floor heating with a lever designed to turn it on / off. Such devices have no other functions. The average price for them is 15 euros.

- Electronic devices. Their functionality is similar to the mechanical version, but it is implemented differently. The electronic model provides for the presence of a digital screen on which the current or set parameters are displayed. Also on devices you can see several buttons. They may have arrows with up and down signs, which serve to gradually change the temperature regime. Estimated cost – 20 euros.

- Models with programming. Adjusting the temperature of the underfloor heating using such a device allows you to both maintain stable heating and change it automatically depending on time. Models are on sale that have the ability to program the temperature regime during the day and on the days of the week. This function allows you to save energy, which means money and at the same time live in comfortable conditions. For example, the temperature can be lowered when all family members are absent, and raised before they return. Some modifications, in addition to the stationary unit located on the wall, are equipped with portable control panels. Now on sale there are models that adjust the work using a computer or tablet. The simplest modification, which provides for the ability to set the floor temperature in time, will cost no less than 40 euros, and a heaped device can cost more than one thousand.

- Multizone modifications. These thermostats control several circuits and maintain individual parameters in each of them..

- Sensory models. The list of functions performed by these devices is the same as for electronic models. But they are equipped with touch buttons, not tactile ones. The cost is higher.

- Radio thermostats and controllers. Such systems supplied by European manufacturers are new to the domestic market. For example, Uponor systems consist of radio-controlled servo mechanisms, a radio thermostat that monitors sensor readings, and a radio controller that receives data from the thermostat and transmits it to the servos. The kit also includes an SMS-module that allows you to control the system via mobile communication and monitor its status..

Water floor thermostat sensors

Before using the regulating device, you need to know how to regulate the temperature of the warm floor and what elements the system consists of..

Temperature control sensors monitor the temperature:

- underfloor heating;

- indoor air.

As a rule, sensors that monitor the air condition are located in the thermostat housing. This has both a positive point (no installation problems) and a negative one (some difficulties arise). Read also: "Which temperature sensor for underfloor heating to choose and how to install it correctly".

The fact is that when installing the thermostat, a number of conditions must be observed:

- there should be no sources of cold or warm air in the immediate vicinity of the device;

- sunlight cannot fall on him;

- lack of drafts;

- it must be placed so that the device can display the temperature in a given room as accurately as possible, which means that it must be installed at a height of 1 to 1.5 meters from the floor surface.

A remote floor sensor is a small device attached to the end of a long cable. This device must be fixed to the floor at a distance of at least 50 centimeters from the walls. It should be installed at an equal distance in relation to the nearest pipes with a heat carrier. The opposite end of the cable is led to the thermostat and connected to the required terminals (read: "Correct installation of the underfloor heating thermostat and operating conditions").

Install the floor sensor before pouring the screed when laying the heating circuit. But since the devices can break, it is advisable to place them in a special corrugated sleeve to ensure the possibility of replacement. The end of the sleeve in the screed must be insulated, otherwise cement mortar may enter it.

The other end is placed in a groove on the wall and placed on the back box of the device. Such a sequence of installation of water floor sensors is not an easy task, but if the device breaks down, it can be changed quickly and easily..

In the case when a flooring system for arranging a warm floor was used, the installation method is similar. In this case, the corrugated sleeve must be attached to the system and not be pinched..

Sometimes, provided that the corrugated hose is not used, depending on the height of the concrete screed and the type of floor surface (soft or hard), there is a need to use a wire with a different density of the protective sheath. Manufacturers produce hard and soft products, as well as wire modifications that are resistant to aggressive environments.

Temperature control automation

Since it is inconvenient to control and adjust the heating system manually, the question arises of how to adjust the warm water floor by automating the process.

For this purpose, devices such as:

- thermostats and thermostats, which control the temperature taking into account the readings from the floor or air temperature sensors in the room, being control devices;

- servo drives, which are actuators for reducing or increasing the amount of coolant entering the loop.

The thermostat is installed, as a rule, one per room, it can be single or multi-zone. Servos (servomotors) are installed on the feed of each circuit.

Thermostats (thermostats) can be mechanical or electronic. The first type is the most inexpensive and reliable. Assumes manual setting of the required temperature range. An electronic regulator of a water heated floor – allows you to control several parameters at once and even program the heating system (depending on the capabilities of the model, as well as the requirements for the temperature in a particular zone, by the time of day, etc.). These are more expensive devices.

Working with collector flow meters

Hydraulic balancing of the underfloor heating loops consists in regulating the flow rate in each coil. Depending on the length, a different amount of the incoming heat carrier may be required in order for it to cool down exactly to the calculated value when passing through the loop. Quantitatively, the required flow is determined as the ratio of the heat load on the loop to the product of the heat capacity of water or another heat carrier by the temperature difference in the supply and return: G = Q / s * (t1 – t2).

You can often find recommendations to determine the flow rate of the coolant according to the performance of the circulation pump, that is, to divide its supply in proportion to the ratio of the lengths of the loops. Such advice should be avoided: besides the fact that the length of each coil is quite difficult to calculate, one of the most important rules is violated – to choose equipment parameters based on the needs of the system, and not vice versa. Attempts to distribute the flow rate in the described manner almost always lead to the fact that the flow in the loops differs significantly from the calculated values, which makes further adjustment of the system impossible..

The very same adjustment of the flow with flow meters is quite simple. In some models, the throughput is changed by turning the body, in others – by rotating the stem with a special key. The scale on the body of the flow meter indicates the flow rate in liters per minute, you just need to set the appropriate position of the float. Almost always, when the throughput of one flow meter changes, the flow rate in the remaining loops changes, therefore, the adjustment is carried out several times, sequentially calibrating each branch. If such changes are especially pronounced, this indicates a lack of throughput of the control valves through which the collector is connected, or about too low performance of the circulation pump..

Criterias of choice

The quality of the underfloor heating system depends on the correct selection of the flow meter. Three types of rotameters are produced:

- Measuring. This type of flow meter is installed with a manual control valve. The control is carried out taking into account the measuring indications.

- Regulatory. Performs only one function – control of the amount of heat transfer fluid entering the water circuits.

- Combined. Such a device combines two actions – adjustment and measurement. The cost of the product is much higher than that of models performing the same type of function..

When buying a flow meter for a warm floor, you should pay attention to the following product parameters:

- Body material. Devices made of brass have high wear resistance. From above, such a case should be plated with nickel. Plastic products are cheaper, but they have a lower strength index..

- The integrity of the device. Before purchasing a rotameter, it is recommended to carefully inspect the body and transparent flask in order to exclude the presence of cracks or other defects..

- Inner part. The spring in the middle of the meter body must be made of stainless steel.

- Flask. The transparent cap with a measuring scale in quality models is made of polycarbonate. Such material is quite strong and has high temperature resistance, which is especially important when used in heating systems..

- Specifications. In the instructions supplied with the gauge device, the temperature level. This figure should be at least 110 degrees. Also no less important is the pressure – at least 10 bar.

- The maximum value of the throughput. The rotameter must be able to conduct at least 2-4 meters of coolant through itself in an hour.

Preparing for installation

Before installing the thermostat, you should carefully study the attached instructions from the manufacturer. Particularly, you should devote time to the section on installation, since the principles of installation of different models of regulators may differ slightly..

Remove the regulator front cover by slowly and carefully removing the control wheel. To do this, carefully hook the element with a screwdriver, and then unscrew the screw. If your model has latches, you can simply press on them with the same screwdriver, and the panel can be removed.

Note – if you cannot remove the cover and you are going to do it by force – think twice. Most likely, you will break the fasteners, and the device will have to be thrown away. Do not rush, it is better to study the instructions more carefully, as practice shows, this helps.

Installation of a floor heating thermostat implies the presence of the following devices:

- Corrugated tube. This item is often included. If for some reason this is not provided for by you, you will have to purchase it additionally. It is best if the tube is 16 mm thick. To find out the required length, measure the distance from the installation point of the regulator to the installation site of the temperature sensor (read: “How to choose and install a temperature sensor for a warm floor”).